VARIMO Metal shelving racks

VARIMO is a professional shelving rack system characterised by quality workmanship, solid construction and variable layout. The shelving rack construction allows screw-less assembly while maintaining high strength and stability.

VARIMO stands for metal shelving racks that adapt to virtually every customers archiving and storage needs.

A sophisticated shelving rack system that is well-used in many areas.

It’s particularly suitable for the following purposes:

VARIMO is a versatile shelving rack system that is able to provide a suitable solution for optimising your warehouse management. VARIMO shelving racks contribute greatly to improving the supply and storage processes of different types of items by creating really suitable conditions for storing them.

The basic design of VARIMO metal shelving racks has a wide range of applications. Other shelving rack modification or extending them with appropriate accessories can adapt the arrangement of shelving racks tailored to the storage of a particular assortment, or it allows a variety of combinations of different types of goods that you need to store.

They suit for archiving corporate documentation perfectly, whether it’s stored freely, in files or archive boxes. They’re very serviceable in warehouses for products, packaged as well as stacked goods or spare parts. Museums and galleries can use these shelving racks in warehouses to store their collections, both in open and closed shelving rack units.

The use of VARIMO shelving racks in hotel and accommodation facilities and hospitals is also evaluated very positively and they also find great use in schools and educational facilities. VARIMO shelving racks can also be widely used in workshops, manufacturing and processing operations. Last but not least, these shelving racks can be used in households - most often in a store-room, cellar or they can help you finally bring some order to the garage and arrange everything clearly in a small space.

The basic specifications of VARIMO metal shelving racks are described with the structure design and individual elements of the shelving rack system. The information below can practically describe the material structure of VARIMO shelving rack system and its individual elements.

The professional shelving rack system has the following features: quality processing, rigid construction and variable layout.

VARIMO shelving racks are made up of three basic elements: supporting frame, shelves and strengthening beams.

- Shelving rack frame consists of uprights, top covers and bases under the uprights.

- Shelf is composed of crossbar shelves and panels in the appropriate dimensions.

- Strengthening beam varies according to the way of placement and comes in two options - such as cross bracing or "H" continuous profile.

The shelving rack structure is designed for screw-less assembly, of course, while maintaining high stability.

Surface treatment - galvanisation - is made of a sufficiently thick zinc coating and guarantees excellent shelving rack properties, including long life, representative appearance and easy maintenance.

The undisputable advantages of the shelving racks includes the design of individual structure components:

- Narrower uprights provide more space along the length of the shelf, resulting in a wider clear dimension for loading archival items or goods into the shelving rack.

- Low profile and smaller adjustable step allow the stacking of more shelves while maintaining the shelf height. The shelf edge height is only 30 mm and the shelf adjustment is 25 mm within the shelving rack height.

VARIMO shelving racks are manufactured from certified steel and statically calculated profiles of individual components to secure declared shelving rack load capacity. By combining individual shelving rack parts, the required load capacity as well as the unit dimensions variability are achieved.

VARIMO shelving racks excel in dimensional variability. The shelving racks can be assembled in virtually any configuration, of course, with regard to modular dimensions. Within the same unit, it’s also possible to vary the height as well as the depth of the individual shelving rack uprights.

VARIMO metal shelving racks are available in these basic dimensional modules:

- Shelving rack height: 2000, 2500, 3000, 3500, 4000, 4500 a 5000 mm

- Shelving rack depth: 200, 300, 400, 500, 600, 700, 800 a 1000 mm

- Shelf length: 550, 700, 850, 1000, 1150, 1300 a 1500 mm

By combining the dimensions, we are able to comply with the requirements of the vast majority of customers and help them to solve their storage problems. Thanks to the use of appropriate shelf lengths, we will achieve the best possible use of the space in the entire length of the shelving rack unit. The units don’t have to have the same deep shelves all along their length. If the situation requires (for example, a narrowing around the upright or radiator) or based on a simple customer requirement, the shelf depth can be changed continuously. The possibility to change the height of the shelving rack and the number of shelves above each other in the individual uprights of the shelving rack unit is then a matter of course.

It should also be borne in mind that the dimensions are modular, i.e. rounded to the numbers which simplify the design creation of shelving rack units. The modular dimensions of VARIMO shelving racks help us to better understand the dimensions of each shelving rack component. When designing shelving rack units, it is, however, necessary to take into account the actual dimensions within the usable space so that the new shelving rack fits in the given space.

In a simple way, it can therefore be stated that the shelving rack unit is 18 mm longer (half the shelving rack upright width) at each end, and in each joint of the shelving rack unit the overall dimension increases by 5 mm. Also, the depth of VARIMO shelving rack is increased by the uprights overhang, which comes to 25 mm (for the entire shelving rack depth).

For a better imagination of the described, you can download a file from the Documents to the download section with a clear description and display of the actual dimensions of VARIMO shelving racks.

Load capacity is an important aspect of any shelving rack system and the VARIMO shelving rack system is no exception in this respect. The load capacity of the shelving rack determines the possibilities of storing the required goods or material. A limiting factor here is the shelf load capacity in this case.

VARIMO shelving racks achieve very good results in terms of load capacity. Thanks to the unique shelf structure that consists of individual panels, it’s possible to choose the load capacity from a relatively wide range of options. The bends of the individual panels form the supporting ribs at the bottom of the shelf, which allows achieving the load capacity in virtually all areas using the shelving racks.

The combination of different panel widths and the material used creates a wide range of load-carrying capacities that suit almost all storage requirements. Whether it's regular archiving and storing documents, using shelving racks for warehousing to storing goods and other products, or even in workshops and service shops where you need to store spare parts, semi-finished products or other materials.

The shelving rack uprights don’t lag behind the load capacity of shelves as they always have a sufficient load capacity for the required number of shelves in the given shelving rack upright. The loading of a particular shelving rack upright is determined by the number of shelves that the shelving rack contains, their spacing and the height of the first shelf from the ground.

Shelving rack uprights are manufactured in different material thicknesses to adapt to the intended application and load capacity to a maximum. VARIMO shelving rack frames are sized for sufficient toughness and safe transfer of the used load of the fully loaded shelving rack.

VARIMO shelving rack system shelves guarantee a high load capacity that can be guaranteed provided that the material stored is evenly distributed over the shelf and the load is not just in one point or just on a small area of the shelf. Proper storage therefore guarantees not only the safety of the stored goods, but also the health of the shelving rack operators. The same can’t be guaranteed if the material is stored inappropriately.

It is also important to note that even if the shelving rack system and the shelves themselves have a high load capacity, this doesn’t mean that it is possible to use individual parts of the shelving rack structure to climb the shelving rack or to use it as a support for other storage devices and structures. Exceptions are the cases when this has been accounted for in the actual design of the shelving rack unit.

One of the most important parts of any shelving rack is the frame or shelving rack uprights from which it consists. The shelving rack’s total load capacity depends on them. They transfer all load to the floor and provide the stability of the shelving rack unit. For this reason, the shelving rack frame is the basic element of the shelving rack.

VARIMO shelving rack system is also outstanding thanks to the well-designed upright that combines high strength with a lightweight construction. The profile of the upright is calculated so that it can be as narrow as possible, taking up the least amount of space and minimising the shelving rack’s use restrictions. Its construction is also strong enough to carry the required load.

The load capacity of the shelving racks has been verified at the State Testing Institute in Brno, where the load is verified at twice the nominated load capacity. Therefore, It’s clear and proven that it’s a highly stable shelving rack system, although it might not seem that way at the first glance due to its subtle design.

A VARIMO shelving rack upright consists of a hollow steel profile of approximately square shape with two front projections. Its cross section is slightly reminiscent of the letter "T". On the sides of the upright, there are rectangular holes in a 25 mm raster that are used to hold the crossbar shelves. The hole spacing also determine the height adjustability of the shelves. At the front of the upright, there are holes for the strengthening beam attachment and other shelving rack accessories.

The uprights are equipped with a cover on the upper end to prevent damage to their edges when storing on the top floor of the shelving rack. The lower end of the upright is set into a base which helps to distribute the load evenly into the floor. Depending on the required load capacity of the shelving rack, the base can be either plastic or metal.

Shelves are an important element of the shelving rack unit. Together with the frame, they form the supporting parts of the shelving rack structure. Shelves form a horizontal supporting surface where goods or other materials are stored, and therefore, there is a great emphasis is placed on their design, material and construction.

The biggest advantage of VARIMO shelving rack system shelves is that they are made-up of individual panels. Each panel has a three-fold edge at the bottom, which has a grid function and increases the stiffness and load capacity of the shelf. The transition between the panels within a single shelf doesn’t create any significant edges, so the upper side forms a continuous plane. Another notable advantage of VARIMO metal shelving racks is the shelf thickness, which is only 30 mm. Thanks to this, our shelving rack system achieves better shelving rack usability, because it’s possible to place more shelves in one upright above each other. With the same number of shelves, it also provides a greater spacing and a light dimension between the shelves.

The VARIMO shelving rack system shelf consist of two basic elements, i.e. a load-bearing crossbar shelf and a panel. One shelf is made up of two crossbar shelves that correspond to the depth of the shelving rack, and an appropriate amount of panels. The length of panels then indicate the length of the shelving rack upright.

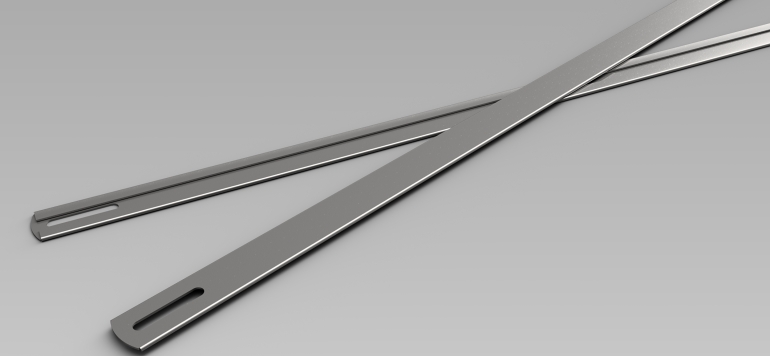

The crossbar shelves provide shelf attachment in the shelving rack frame. The crossbar shelves design create a relatively complex shape, which must secure adjustable and firm connection with the frame, as well as provide a stable support for the panels. This is managed with suitably chosen material and sophisticated profiling of the crossbar shelf’s individual parts. The length of the crossbar shelf always corresponds to the depth of the shelf.

The panels provide a support surface for storing goods in the shelving rack. It’s produced in three widths (100, 200 and 300 mm) and the depth of the shelf is composed of the combination of these widths. Using the appropriate widths also achieves the required shelf load capacity. The panel lengths, which are also the length of the shelf itself, range from 550mm to 1500mm in a 150mm increments (except the last one, which is 200mm). This wide range of lengths allows for considerable variability when creating the shelving rack units. Thanks to their combination, it’s possible to satisfy any shelving rack system requirements in almost every space.

The supplied accessories significantly extend the using options of VARIMO shelving racks. The accessories are mainly used to improve sorting stored goods or to store special and non-standard products. They also allow simultaneous storage of an incompatible item within one shelving rack unit.

The following types of accessories are available for VARIMO shelving racks:

- Side and rear panels

- Side stops

- Partition dividers

- Wardrobe bars

- Dividers

- Wing or sliding doors

The most commonly used types of shelving rack accessories include side stops and side panels which prevents stacked material from slipping towards the side. The side panels are embedded into the shelving rack frame and can be made in galvanised or painted sheet metal, as well as laminated chipboard. With the painted sheet metal, you can choose the desired RAL colour and with laminated chipboard, there is a selection of designs. Side panels can also be supplied in other alternatives, such as from welded nets, perforated sheets, hardened PVC and others.

Side stops are mostly used when storing files and documents. The side stop is formed by a "U" profile inserted between the frame uprights. It’s clipped with hooks. The stop can be set to the desired height in 25 mm increments,

the same holes in the uprights are used for hanging the shelves. The side stops can be galvanised or painted.

The shelves on the VARIMO metal shelving rack can also be equipped with sliding stops that can be placed in any position along the shelf length. It’s used to prevent stored material from flipping, which most often is a documentation type. The advantage of the mobile partitions, is that you can place them in the desired shelf place, so you can use them as end stops.

Wardrobe bars are an appropriate element for hanging clothes on hangers, or other material to store in a vertical position. The dividers divide shelves into individual segments for storing small items such as fasteners, electric materials, or various fittings.

If you need to prevent unauthorised access to the shelving rack, it is also possible to use door on the shelving rack, in addition to the side and rear panels. Doors can be classical winged or sliding, depending on the area where the shelving rack is used, or simply depending on the user's requirement. The advantage is they don’t limit the space in front of the shelving rack. Doors for VARIMO shelving racks can also be unsecured, but in most cases the locking option is used.

Installation manual

On the page (below), you can find a detailed video tutorial and text description to help you construct your VARIMO shelving racks. In case there is any doubt with any part of the instruction manual, please, contact us, we will gladly explain it to you or fill in the missing information.

Před samotnou montáží je nutné prověřit kvalitu podlah, co do únosnosti a rovinnosti a případně navrhnout vhodné příslušenství pro rozložení tlaku působícího od patek sloupů regálových rámů a nebo použít podložky pod patky.

Po dokončení montáže musí být provedena kontrola technického stavu, stability, tuhosti spojů, svislosti a vodorovnosti sestavy regálu.

Regál VARIMO se skládá z těchto součástí:

- Sloupů s perforací pro zavěšení polic

- Plastových nebo kovových patek a plastových krytek pro sloupy

- Traverz pro uchycení polic ke sloupům

- Policových panelů

- a zavětrovacího kříže

Nejprve si určíme jednotlivé strany sloupu. Horní stranu poznáme podle vyraženého nápisu GS na čelní straně sloupu. Poté na spodní stranu sloupu nasadíme plastovou patku a potom ji pomocí kladiva nebo gumové palice narazíme tak, aby sloup dosedl do drážek v patce. Stejný postup opakujeme u všech sloupů.

Na horní stranu sloupu nasadíme plastovou krytku. Krytka jde nasadit lehce a není k tomu potřeba žádné nářadí, případně použijeme gumovou palici. Opět opakujeme stejný postup u všech sloupů.

Rám regálu sestavíme tak, že vždy dva sloupy spojíme k sobě pomocí traverz. Délka traverz je daná hloubkou regálu a jejich počet a rozmístění je závislý na požadované rozteči jednotlivých polic.

Pro uchycení traverz slouží háčky na jejich koncích, které se vsadí do perforace na boční straně sloupů. Potom traverzy doklepneme pomocí kladiva nebo gumové palice do dorazové polohy. Následné zajištění traverzy proti nechtěnému vysunutí provedeme pomocí „jazýčků“ na krajích traverzy tak, že je šroubovákem ohneme dovnitř sloupů.

Takto sestavené rámy regálu postavíme do svislé polohy na vzdálenost délky police. Vezmeme policové panely a jejich konce vsadíme do „perových“ úchytů v traverzách a lehce je doklepneme pomocí gumové palice.

Police regálového systému VARIMO jsou sestaveny z jednotlivých panelů o různé šířce, jejichž kombinace dá dohromady požadovanou hloubku police.

Takto pokračujeme u všech polic v regálu.

Následně přišroubujeme na zadní stranu regálu zavětrování. Zavětrování se skládá ze dvou plochých profilů, které pomocí šroubů přichytíme ke sloupům. Ve sloupech jsou již připravené otvory, zvolíme pouze vhodné umístění zavětrování přibližně uprostřed regálu na výšku. K přišroubování použijeme standardní stranový klíč a dodaný nástrčný trubkový klíč pro přidržení matky uvnitř sloupu.

Na závěr, když je regál sestaven, ho přesuneme na požadované místo a zkontrolujeme jeho stabilitu. Dle potřeby můžeme případně regál ukotvit do podlahy (při použití kovových patek) nebo do zdi.

Placing a galvanised sheet metal side panels into the shelving rack:

Once the shelving rack frame has been installed, i.e. after placing the crossbar shelves and bases on the shelving rack uprights, place the frame in a suitable position (preferably horizontal). Insert the sheet metal panel into the assembled frame from the top part. This panel then passes through a groove on the inside of the upright. The top covers must be adjusted with a suitable notch for use in the upright.

Placing a galvanised sheet metal panel on the back of the shelving rack:

First, assemble the entire shelving rack (without strengthening beams), then apply a sheet metal filling on the back. It is applied by folding the metal sheet vertically and gradually placing it in the shelving rack. It is necessary to fit it on the sides between the shelf and the projections on the uprights. Secure the metal sheet with strengthening beam elements, evenly spaced at the height of the shelving rack. These elements also serve to reinforce the shelving rack in the longitudinal direction.

The VARIMO metal shelving system has a number of certifications, i.e. it belongs to the certified shelving rack system that complies with the strict criteria of different users. The certificates awarded show that quality is paramount for us and we put great emphasis on the implementation of VARIMO shelving racks.

One of the most important certifications is the one that testifies checking the static parameters of the shelving rack system, demonstrating its strength and stability under any circumstances. For this reason, we have tested VARIMO shelving racks at the State Testing Institute in Brno. They passed all the obstruction tests and easily complied with the declared load capacity values.

VARIMO metal shelving racks are manufactured within the EU in the Czech Republic, specifically in our production plant in Chotusice near Kutná Hora.

Production takes place to the fullest extent in automated operation, which minimises the risk of manufacturing errors and the individual parts of shelving racks reach high accuracy tolerances. For the production of VARIMO shelving racks, we use only certified steel that also comes from sources within the EU. The entire production takes place in accordance with the relevant European standards.

Our biggest focus is the principle of stock movement control and related logistics so that the production and unloading orders take place efficiently and fluently without unnecessary delay. This system allows us to ship our shelving rack deliveries to our customers at short notice and without unnecessary extra costs, which is appreciated by our business partners as well as customers.

On this page, you can find documentation to download in case you need it in a printed form. There are stored basic documents for VARIMO metal shelving racks. If you need any other or more detailed information, please contact us via the contact form or one of the contacts listed.

- Cataloque of VARIMO Shelving racks (MITO) online browsing with a possibility to download